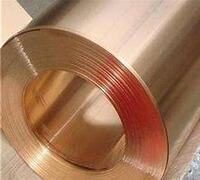

Copper strip production procedure

Making components: According to the alloy component composition of different brands, make proportions according to actual requirements and carry out initial processing.

Smelting: Thaw the components in the melting heating system. At the exact same time, heater analysis is required. Typically, chemical analysis and optical range analysis, and the proportion and feeding are changed in time according to the evaluation results.

Ingot spreading: There are up drawing approaches, semi-continuous casting, horizontal continuous casting, iron mold spreading, and so on. Semi-continuous casting refers to the downward circulation of molten water, with the advantage of the most effective accuracy. The higher drawing method describes the higher flow of molten water, with the advantage of excellent accuracy. Horizontal constant casting refers to the direct drawing of liquified water, cooling down and straight on the rolling mill, and rolling it right into coils, with the negative aspect of poor accuracy. Iron mold and mildew spreading describes the direct pouring of liquified water into the iron mold, with the negative aspect of the worst precision.

(copper strip)

Milling: Surface area processing of ingots.

Warm rolling describes the rolling of poor ingots after heating yet prior to cooling down, without annealing.

Straightening-milling: the surface area of the ingot is rough, and the internal framework hangs.

Cold rolling refers to the procedure of home heating and cooling down the billet while annealing and rolling.

Annealing: Bell heater annealing is typically used for semi-finished products; annealing is uniform but controlled by thickness, and firmness is controlled by annealing time.

Pickling: Clean the dust after annealing, and pickling is normally called for after annealing.

Ending up (intermediate) rolling: The surface is really smooth, and the internal structure is fairly uniform and limited.

Cleaning up and leveling: Establish the monotony of the plate surface area.

Longitudinal shearing or transverse shearing: The copper strip to be divided into strips is longitudinally sheared and rolled right now, and the plate is transversely sheared right now.

Examination: Conduct mechanical homes and chemical make-up tests

Packaging and warehousing: Inspect products with qualified quality, mark and register them for warehousing as needed.

Method for treating staining of copper strip surface

Control the focus of acid throughout pickling. When the acid focus is high, the residual acid attached to the surface of the copper strip is difficult to wash off and speeds up the pollution of the cleansing water, which is simple to triggers the recurring acid concentration in the cleansing water to be expensive, making the copper strip after cleansing more likely to alter shade. When figuring out the concentration of the pickling remedy, attempt to decrease its concentration as much as possible while having the ability to clean up the oxide layer externally of the copper strip.

Control the conductivity of distilled water. Control the conductivity of pure water that is, manage the material of harmful substances such as chloride ions in distilled water.

Control the conductivity of warm cleaning water and passivation agent. The increase in the conductivity of hot cleaning water and passivation agent is generally due to the residual acid brought into the running copper strip. Under the condition of guaranteeing the quality of the distilled water utilized for cleaning, managing the conductivity indicates regulating the quantity of recurring acid.

Make sure that the copper strip is dry. Partially shut the outlet of the air cushion heater coiling, and utilize a dehumidifier and ac unit in the regional shut gadget to control the moisture and temperature level of the copper strip during curling within a specific array.

Concerning Copperchannel

Copperchannel is a trusted global chemical material supplier & manufacturer with over 12 years experience in providing super high-quality copper and relative materials. The company export to many countries, such as USA, Canada,Europe,UAE,South Africa, etc. As a leading nanotechnology development manufacturer, Copperchannel dominates the market. Our professional work team provides perfect solutions to help improve the efficiency of various industries, create value, and easily cope with various challenges. If you are looking for copper alloy, please send an email to: nanotrun@yahoo.com

Inquiry us