Advancements in Round Niobium Powder: Driving Innovation and Sustainability Throughout High-Tech Industries

Spherical niobium powder stands as a testament to the recurring innovations in material science, playing an increasingly essential role in modern-day sectors. Niobium, recognized for its high melting point, low thickness, and outstanding deterioration resistance, locates itself changed right into a versatile spherical powder type that provides unparalleled advantages. This sort of powder is produced making use of sophisticated strategies like gas atomization or plasma spheroidization, ensuring bits are completely rounded with consistent size distribution. Such characteristics significantly boost flowability and packaging density, which are critical elements for applications in additive manufacturing and steel shot molding. The unique residential properties of spherical niobium powder enable it to hold up against severe settings, making it vital in aerospace components, superconducting magnets, and other high-performance materials. Additionally, this powder’s capability to perform electrical energy and warm successfully, together with its compatibility with human cells, opens up new opportunities in electronics and medical tools. As r & d initiatives continue to discover unique applications, spherical niobium powder is set to play a crucial function fit the future of innovation and market.

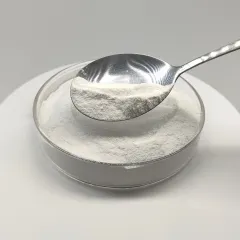

(Spherical Niobium Powder)

The manufacturing procedure of spherical niobium powder is a marvel of engineering precision and advancement. Manufacturers utilize cutting-edge innovations to produce powders that satisfy the stringent demands of numerous industries. Gas atomization entails spraying liquified niobium with a nozzle right into a chamber where it strengthens into spherical droplets upon call with a cooling medium. Alternatively, plasma spheroidization utilizes high-energy plasma to melt angular niobium powders, which then cool down swiftly right into balls. Both methods cause powders that display minimal porosity and remarkable mechanical properties compared to their irregularly designed equivalents. The boosted flowability and consistency of spherical niobium powder make it specifically ideal for 3D printing, where it can be used to develop complex geometries with outstanding toughness and toughness. Past additive production, this powder works as an essential component in the manufacturing of superalloys, contributing to improved performance in jet engines and commercial wind turbines. In the world of electronic devices, the powder’s conductivity and thermal stability support the growth of extra reliable capacitors and resistors. Medical applications benefit from niobium’s biocompatibility, bring about the development of implants that reduce the danger of denial by the body. With each passing day, the prospective applications for spherical niobium powder increase, driven by the ruthless quest of innovation across several sectors.

As the demand for high-performance materials grows, so too does the marketplace for spherical niobium powder. Industries such as aerospace, vehicle, and electronic devices are significantly dependent on this powder to fulfill the difficulties of miniaturization, efficiency, and sustainability. Aerospace makers use niobium-based alloys for elements that need to endure extreme temperatures and stress, making sure trusted operation in space goals and commercial flights. Automotive companies explore making use of spherical niobium powder in electric automobiles, leveraging its lightweight homes to enhance gas efficiency and extend driving array. Electronics makers value the powder for its duty in producing compact and long lasting digital tools efficient in operating under diverse problems. Additionally, the medical field capitalizes on niobium’s biocompatibility to establish innovative services for individual treatment. Environmental considerations also prefer the adoption of round niobium powder, as niobium mining practices are typically extra lasting than those of some different steels. Reusing initiatives additionally promote a circular economic climate by recuperating and recycling niobium from end-of-life products. As awareness of these advantages spreads, financial investment in round niobium powder is likely to boost, fostering technical progress and broadening its energy in a globe increasingly focused on innovative materials and lasting techniques. The continued advancement of spherical niobium powder guarantees to unlock brand-new opportunities for development throughout a broad variety of sectors.

TRUNNANO is a supplier of nano materials with over 12 years experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. Trunnano will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you want to know more about Spherical Niobium Powder, please feel free to contact us and send an inquiry.(sales5@nanotrun.com)

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us