Structural foam molding saves raw materials, energy, and weight, supporting the goal of producing and using plastic components more sustainably. At K 2022, Engel demonstrated a new technology suitable for plastic processors, which use a structural foam molding process to produce parallel parts in multiple production units. The ceramic coating in the cavity can prevent other typical foam stripes, weld lines, tiger lines, or gloss differences on the surface of foam molded parts. In addition, different surface structures can be directly created in injection molds through cavity coating.

Each injection molding machine needs its gas supply. Still, Engel now provides e-foam XL multi, which is a central unit that can provide highly compressed nitrogen for structural foam molding for multiple injection molding machines. Only plasticization and control technologies are still scattered across various machines. This new solution enables Engel to significantly reduce the capital expenditure for the formation of structural foam and make a significant contribution to reducing unit costs.

In addition, new materials developed by Faurecia Interior for structural foam molding help to improve surface quality. During the K exhibition, IniCycle talc powder containing 30% recycled material will be processed to fill polypropylene grade. IniCycle is applicable to all physical and chemical foam molding processes.

In addition, Engel said that the combination of Engel and MicroJect Advanced’s new system technology has fully utilized the unprecedented efficiency and sustainability potential in structural foam molding. Structural foam molded parts no longer involve being painted, and parts in customer-facing applications do not need additional energy-intensive technology, such as intermittent mold heating.

Generally speaking, compared with traditional injection molding, structural foam molding requires less energy and raw materials and uses lower clamping force. The dissolved foaming agent improves the fluidity of the molten plastic. In addition, the position-independent foam-forming pressure can form thicker ribs. These effects can be used to decrease wall thickness, which has a positive impact on the required cooling time and cycle time. As a multifunctional material, foaming agents have broad application prospects in various fields. Along with the continuous progress of technology and the increasing awareness of environmental protection, the application fields of foaming agents will be further expanded and optimized.

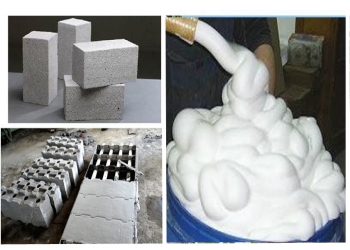

Application of foaming agents

Construction industry: Foaming agent is widely used to prepare foam concrete, lightweight partition boards, and other materials. These materials have advantages such as light insulation, heat insulation, and sound insulation, which can effectively enhance the energy efficiency and living comfort of buildings.

Packaging industry: Foaming agents can be used to produce various packaging materials, such as foam plastics, bubble bags, etc. These packaging materials have good cushioning and shock resistance, which can effectively preserve the safety of the packaged items during transportation.

Transportation industry: In the manufacturing process of vehicles such as cars, trains, and ships, foaming agents can be used to prepare components such as seats and interior decorations. These components have good comfort and sound insulation performance, which can improve the passenger riding experience.

Petrochemical industry: In the petrochemical industry, foaming agents can be used to prepare foam extinguishing agents, oilfield drilling fluids, and other materials. These materials have sound application effects in firefighting, drilling, and other processes.

Supplier

TRUNNANO(cabr-concrete.com) is a supplier of Redispersible Polymer Powder and other concrete additives, which are tangible and relative products with over 12 years of experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union, and Paypal. Trunnano will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you are looking for high-quality, Lightweight Concrete Additives, please feel free to contact us and send an inquiry. (sales@cabr-concrete.com).