Intro to Aluminum Oxide Crucibles

Light weight aluminum oxide crucibles, likewise called alumina crucibles, are vital devices in high-temperature applications as a result of their remarkable thermal security, chemical inertness, and mechanical stamina. These crucibles are commonly utilized in industries ranging from metallurgy to lab study, where precise control over temperature level and response conditions is important. This post looks into the structure, making procedures, applications, market trends, and future leads of light weight aluminum oxide crucibles, highlighting their pivotal duty in modern scientific and commercial improvements.

(Aluminum Oxide Crucibles)

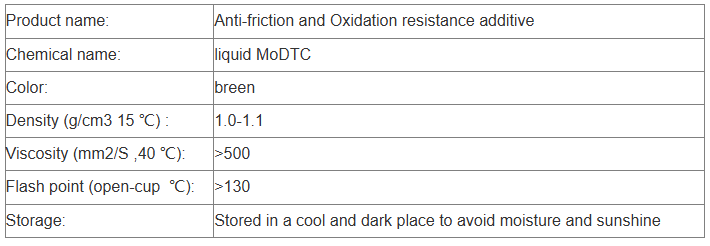

Composition and Production Process

Light weight aluminum oxide crucibles are mainly made up of light weight aluminum oxide (Al ā O ā), which can be located in different pureness degrees depending upon the application demands. High-purity alumina, typically exceeding 99%, is chosen for its remarkable residential properties. The manufacturing process begins with resources such as bauxite ore, which undergoes calcination to get rid of contaminations and kind alpha-alumina powder. This powder is then shaped right into crucibles utilizing strategies like completely dry pressing, slide spreading, or shot molding. After shaping, the crucibles go through sintering at temperatures between 1600 Ā° C and 1800 Ā° C, causing thick and consistent structures. Post-sintering therapies, consisting of grinding and brightening, make certain accurate measurements and smooth surfaces. The end product is a robust crucible efficient in standing up to severe temperature levels and severe chemical settings.

Applications Across Various Sectors

Metallurgical Market: In metallurgy, aluminum oxide crucibles are vital for melting and refining steels. Their capacity to hold up against high temperatures and resist chemical reactions makes them suitable for dealing with liquified steels like light weight aluminum, copper, and precious metals. The crucibles’ non-reactive nature ensures that the pureness of the melted steel is maintained, stopping contamination and making certain constant high quality. Metallurgical makers rely on these crucibles for effective and reliable production processes, improving performance and reducing waste.

Laboratory Research study: Aluminum oxide crucibles are extensively made use of in lab settings for carrying out high-temperature experiments and evaluations. Their chemical inertness and thermal security make them appropriate for applications such as gravimetric analysis, ash web content decision, and material testing under severe conditions. Scientist worth these crucibles for their capacity to provide precise and reproducible results, helping with clinical explorations and advancements. Laboratories geared up with aluminum oxide crucibles can perform a large range of explores confidence and accuracy.

Ceramic and Glass Manufacturing: In the ceramic and glass markets, light weight aluminum oxide crucibles play an important function in the production of sophisticated materials. They are used for melting and processing ceramic powders and glass sets, where exact temperature level control and resistance to chemical assault are important. The crucibles’ longevity and warmth resistance enable the creation of high-grade ceramics and glass items, meeting rigid sector criteria. Makers take advantage of the enhanced efficiency and durability of aluminum oxide crucibles, enhancing efficiency and reducing downtime.

Chemical Processing: Chemical handling plants utilize aluminum oxide crucibles for reactions involving destructive chemicals and heats. Their resistance to acids, antacid, and other hostile substances guarantees safe and reliable operation. These crucibles are employed in processes such as synthesis, distillation, and filtration, where preserving the honesty of catalysts and items is vital. The use of aluminum oxide crucibles boosts safety and security and operational performance, making them essential tools in chemical processing facilities.

Market Patterns and Growth Drivers: A Positive Viewpoint

Developments in Material Science: Advancements in material science have expanded the abilities of aluminum oxide crucibles. Advanced sintering techniques enhance thickness and reduce porosity, enhancing mechanical residential properties. Nanotechnology and composite products provide new possibilities for boosting thermal conductivity and wear resistance. The assimilation of smart sensors and automation in assembly line boosts effectiveness and quality control. Suppliers taking on these technologies can use higher-performance light weight aluminum oxide crucibles that satisfy evolving market demands.

Sustainability Campaigns: Environmental understanding has driven need for lasting materials and practices. Light weight aluminum oxide crucibles align well with sustainability objectives because of their abundant raw materials and recyclability. Producers are checking out green production approaches and energy-efficient procedures to minimize environmental influence. Innovations in waste reduction and source optimization additionally enhance the sustainability profile of light weight aluminum oxide crucibles. As industries focus on eco-friendly campaigns, the adoption of light weight aluminum oxide crucibles will certainly remain to grow, placing them as key players in sustainable solutions.

Medical Care Innovation: Rising health care expense and an aging population improve the need for advanced clinical tools and pharmaceuticals. Light weight aluminum oxide crucibles are utilized in the production of high-purity materials required for clinical implants, medicine formulas, and analysis tools. Their biocompatibility and chemical inertness ensure client security and item integrity. Producers concentrating on healthcare innovation can take advantage of the expanding market for medical-grade light weight aluminum oxide crucibles, driving development and distinction.

( Aluminum Oxide Crucibles)

Difficulties and Limitations: Browsing the Path Forward

High Initial Costs: One difficulty connected with light weight aluminum oxide crucibles is their reasonably high initial price compared to typical products. The complicated manufacturing process and specific devices contribute to this cost. Nevertheless, the premium efficiency and prolonged life-span of light weight aluminum oxide crucibles typically justify the investment gradually. Suppliers should consider the in advance expenses against long-lasting advantages, thinking about factors such as minimized downtime and enhanced product high quality. Education and learning and presentation of worth can help get over price barriers and promote wider adoption.

Technical Knowledge and Handling: Proper usage and maintenance of light weight aluminum oxide crucibles require specialized knowledge and ability. Operators require training to deal with these accuracy devices properly, making sure optimum efficiency and durability. Small-scale producers or those unfamiliar with innovative machining strategies might face obstacles in making best use of device utilization. Connecting this space through education and learning and accessible technological support will certainly be vital for wider adoption. Encouraging stakeholders with the needed abilities will unlock the complete capacity of aluminum oxide crucibles across industries.

Future Prospects: Advancements and Opportunities

The future of aluminum oxide crucibles looks appealing, driven by enhancing demand for high-performance materials and progressed manufacturing innovations. Recurring research and development will cause the creation of brand-new qualities and applications for aluminum oxide crucibles. Developments in nanostructured porcelains, composite products, and surface design will even more boost their performance and increase their energy. As sectors prioritize precision, effectiveness, and sustainability, aluminum oxide crucibles are positioned to play a pivotal duty in shaping the future of manufacturing and innovation. The continuous development of aluminum oxide crucibles assures interesting possibilities for development and growth.

Conclusion: Accepting the Accuracy Transformation with Aluminum Oxide Crucibles

To conclude, aluminum oxide crucibles are indispensable parts in high-temperature applications, providing unequaled thermal security, chemical inertness, and mechanical toughness. Their wide-ranging applications in metallurgy, lab study, ceramic and glass manufacturing, and chemical handling highlight their adaptability and relevance. Understanding the benefits and obstacles of light weight aluminum oxide crucibles enables suppliers to make informed decisions and capitalize on arising possibilities. Embracing light weight aluminum oxide crucibles indicates welcoming a future where accuracy meets dependability and advancement in modern-day manufacturing.

Vendor

Alumina Technology Co., Ltd focus on the research and development, production and sales of aluminum oxide powder, aluminum oxide products, aluminum oxide crucible, etc., serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services. If you are looking for high quality alumina cylindrical crucible, please feel free to contact us. (nanotrun@yahoo.com)

Tags: crucible alumina, aluminum oxide crucible, alumina crucible

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us