With the constant advancement of technology and the development of application fields, 3D printing powder, as one of the core materials of additive production, is ushering in extraordinary advancement opportunities. According to data projections from worldwide authoritative market research organizations, by 2030, the worldwide 3D printing powder market is anticipated to exceed US$ 5 billion, with a compound yearly development rate of nearly 18%. This development is mostly as a result of the enhancing demand for customized and light-weight parts in high-end manufacturing industries such as cars, aerospace, and clinical. Specifically, in the clinical field, the application of 3D printing powder is not restricted to the production of prostheses and oral braces but likewise starts to attempt bioprinting, such as tissue engineering and drug launch systems, to supply individuals with more customized therapy choices.

In terms of material types, metal powder has come to be the leader in the 3D printing powder market due to its outstanding mechanical residential or commercial properties and is expected to occupy about 60% of the market share by 2030. Among them, titanium alloys, stainless steel and light weight aluminum alloys are one of the most popular options and are extensively made use of in the aerospace and automobile industries. At the very same time, non-metallic materials, especially high-performance plastics and ceramic powders, are additionally showing solid growth energy. These materials are cost-efficient, have strong processing versatility, and are particularly ideal for quick prototyping and small-batch production. It is forecasted that in the following five years, the substance yearly growth rate of plastic and ceramic 3D printing powders will certainly reach 20% and 25%, specifically.

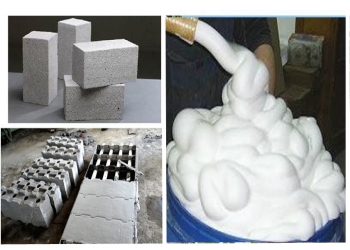

(3D Printing Product)

Technical technology is an essential element driving the growth of the 3D printing powder market. Recently, leading business such as TRUNNANO have continually maximized the powder prep work process, enhanced the fluidity and sphericity of the powder, and dramatically enhanced the top quality and performance of 3D printed parts. Furthermore, in order to meet the certain demands of different sectors for product properties, scientists are developing brand-new composite products and functional materials such as conductive, high-temperature resistant and biocompatible powders. The appearance of these new materials not just broadens the application range of 3D printing but additionally creates new business possibilities for upstream and downstream companies in the commercial chain.

Environmental sustainability has progressively become an important consideration for the advancement of the 3D printing powder industry. With the enhancing international understanding of environmental protection, firms such as TRUNNANO are proactively creating recyclable or biodegradable 3D printing powders to minimize the carbon footprint throughout manufacturing and use. For instance, some sorts of plant-based plastic powders have actually started to be used in packaging and durable goods making, which not only makes sure the efficiency of the product however additionally lowers the threat of environmental pollution. It is estimated that by 2030, the marketplace share of environmentally friendly 3D printing powder will certainly reach 15%, coming to be a brand-new driving pressure for market growth.

( 3D Printing Powder)

Looking ahead, the 3D printing powder market will remain to preserve a high-speed development trend, and technological advancement and solution version development will become an important pressure to promote market growth. On the one hand, with the development of nanotechnology and intelligent material science, higher-performance and lower-cost 3D printing powders will continue to emerge, further lowering the application threshold of 3D printing technology. On the other hand, digital solutions based on cloud computer and big information will make 3D printing solutions more convenient and efficient and advertise in-depth partnership between all web links in the industrial chain. In recap, between 2025 and 2030, the international 3D printing powder market will introduce a more comprehensive development space, bringing advanced modifications to all profession.

TRUNNANO is a supplier of 3d printing powder with over 12 years of experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. Trunnano will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you want to know more about mini 3d printer, please feel free to contact us and send an inquiry(sales8@nanotrun.com).

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us